When complete, the entire 700-foot-long PIP-II accelerator will have a total of 23 cryomodules. Engineers from France, India, Italy, the United Kingdom and United States are working together to design and build the cryomodules, and engineers from Poland are working on the cryogenics distribution system for the new accelerator.

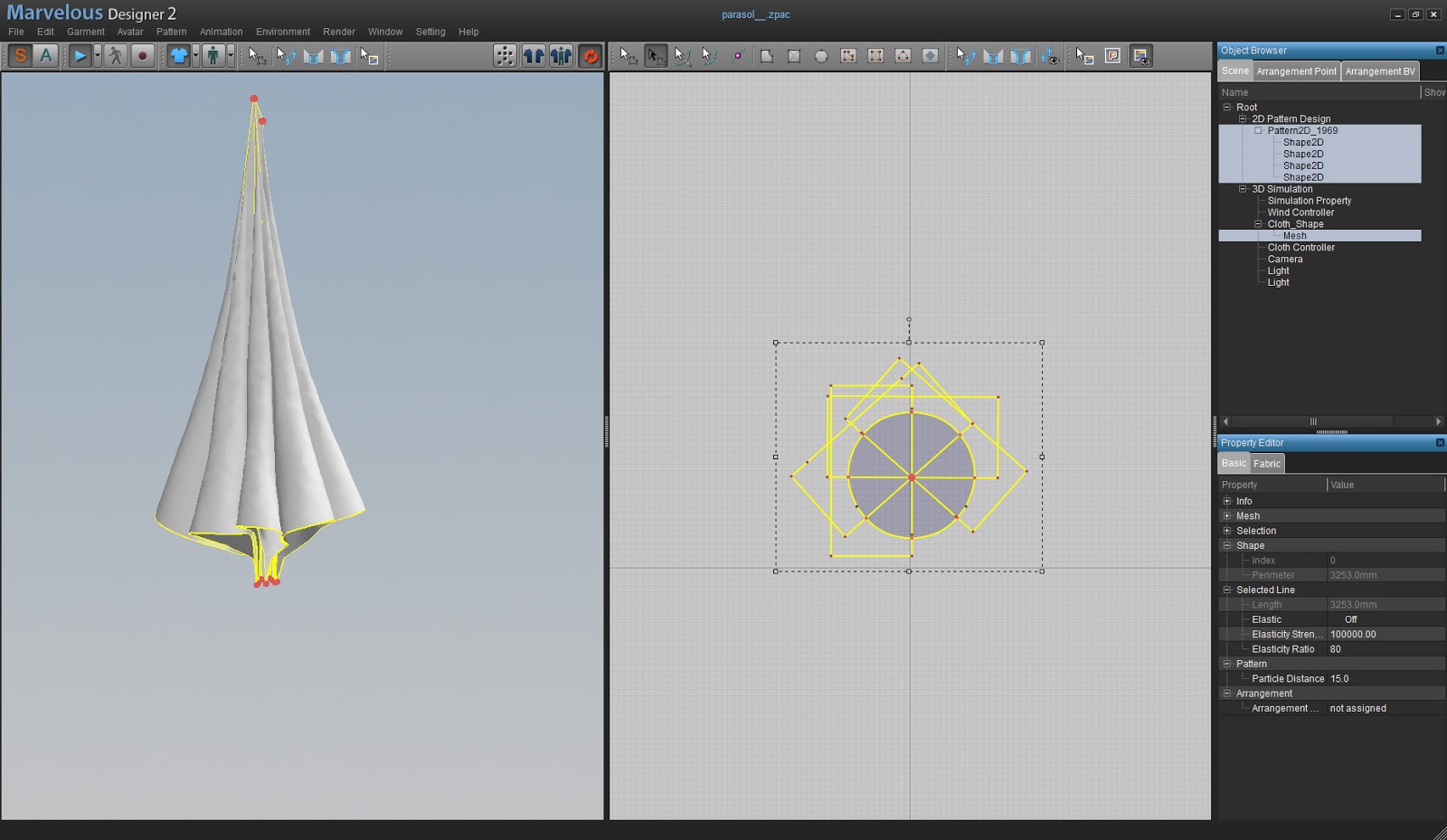

with significant international contribution. It will also provide intense proton beams for the lab’s future experimental programs.Ī truly global effort, PIP-II is the first particle accelerator project in the U.S. The new accelerator will help generate the world’s most powerful neutrino beam for the international Deep Underground Neutrino Experiment, hosted by Fermilab. Like a high-tech refrigerator, the cryomodules that house the PIP-II cavities cool the cavities down to minus 271 degrees Celsius and keep them at that temperature. PIP-II’s accelerator cavities are made of niobium, a material that becomes superconducting at ultracold temperatures. These cavities boost the energy of a particle beam as it travels through one after the next. They house structures called superconducting accelerator cavities, which are lined up end-to-end inside the cryomodule. Ramping up energy, cooling down cavities, working across bordersĬryomodules are the largest components of a superconducting particle accelerator. This is the SSR1 cryomodule of the PIP-II accelerator. Researchers and engineers from five countries have been collaborating on the design and construction of these cryomodules, work that has remained relatively uninterrupted during the lab’s teleworking period.Ĭryomodules are the largest components of a superconducting particle accelerator. This is especially true for those who are designing the PIP-II cryomodules, large metal structures that keep superconducting accelerator components chilled to just a few degrees above absolute zero as they propel protons to close to the speed of light. In many ways, years of videoconferencing with their international partners has prepared the team to continue making progress from home. While certain aspects of the accelerator project can be carried out only in a laboratory, such as making and testing components, the international team of engineers and scientists can advance other aspects, like component design and working on the machine’s detailed blueprints, from their home offices. With people around the world working from home during these unprecedented times, many Fermilab employees are working remotely, and this includes work on the design of Fermilab’s PIP-II accelerator.

0 kommentar(er)

0 kommentar(er)